Composition: The product is the two-component self-dry coating composed of aliphatic series isocyanate component and senior acrylic resin, pigment, additive, solvent and etc.

Performance: The aliphatic series isocyanate paint has high weather resistant, chemical resistant, acid-alkaline proof properties, and excellent mechanical performance; the luster is adjustable and the paint film is full and beautiful. This product can withstand long-term ultraviolet irradiation, and the paint film has no pulverization with less color change. This paint can be used together with other products to protect the substrate for 8 to 10 years, and is a commonly used product for outdoor anticorrosive coating.

|

|

|

Good weather resistance The paint can be in outdoor as long ultraviolet irradiation, paint film is not pulverization. |

Chemical resistance The paint has excellent chemical resistance, resistance to acid and alkali, acid rain, salt fog, salt etc.. The film can resist atmospheric corrosion, powerful protection material. |

|

|

|

Excellent mechanical properties It has excellent adhesion, strong impact resisance and flexibility. |

Beautiful decorative The paint gloss can be adjusted, the film is full and beautiful. |

Application: The paint is often used for the surface of ships, bridges, lamps and other outdoor steel structure, cement and building materials, to decoration and corrosion.

Product specification

Paint film color: specified by the customer

Mixing ratio: Flat products: main paint: curing agent=20:4

High optical products: main paint: curing agent=20:5

Technical parameters

| Item | Index |

| Color | specified by the customer |

| Fineness | ≤30μm |

| Viscosity(painting-4) | 50~80s |

| Adhesion(Row lattice method) | 1 |

| Flexibility | 1mm |

| Drying time(23±2℃) | surface dry:1h hard dry:24h |

| Impact strength | 50kg.cm |

| Gasoline resistance(24h) | Don't fall off, no wrinkle, no bubble, allow a slight discoloration |

| Artificial accelerated aging(800h) | There is no obvious cracks, discoloration ≤3 grade, the loss of light ≤ 3 grade |

| Salt fog resistance(800h) | The film had no change |

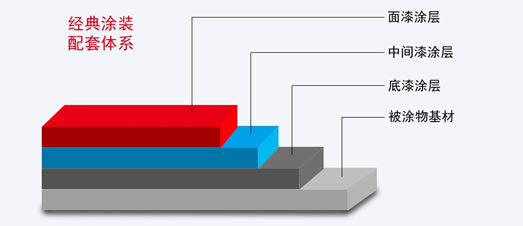

Supporting system

Aliphatic series isocyanate paint can be applied to various industrial environments:

•Anti-corrosion of steel structure: epoxy zinc-rich primer + epoxy micaceous iron oxide intermediate paint + Aliphatic series isocyanate paint

•Bridge preservation: epoxy zinc-rich primer + epoxy micaceous iron oxide intermediate paint + Aliphatic series isocyanate paint;Inorganic zinc rich primer + Epoxy sealer + epoxy micaceous iron oxide

intermediate paint + Aliphatic series isocyanate paint

•Engineering machinery coating: Epoxy primer + Aliphatic series isocyanate paint

•Building exterior decoration: Epoxy sealer + Epoxy paint + Aliphatic series isocyanate paint

Construction method

1、Base material processing

The coated base material surface must carry out thorough removal of grease, scale, rust, old coating, and etc., using shot or sand blasting method, to reach Sweden derusting standard Sa2.5 grade and roughness of 30-70μm, manual derusting methods can also be adopted to reach Sweden derusting standard St3 grade and roughness of 30-70μm.

2、Mixture

According to the weight ratio (the label on the product packaging shall prevail)

When mixing, under the condition of stirring the main agent continuously, slowly pour in curing agent to make it fully ad evenly stirred.

20 min after curing of the well mixed coating, filter with 60-80mesh screen, and pour into another container for spare use.

The mixed coating is valid for 3 hours; please arrange the use according to the construction progress.

3、Construction conditions

Coating operation shall be performed as soon as possible after the substrate processing, generally not exceeding 8 hours. The substrate surface temperature and environmental temperature are generally no less than 10℃, the surface temperature shall be at least 3℃ higher than the dew point temperature, and the relative humidity of the air shall not exceed 85%.

4、Coating method

This coating can use brush coating, airless spraying and auxiliary air spraying method for construction.

5、Dilution

Generally the coating shall use the matching thinner to adjust viscosity and cleaning tools.

6、Coating intervals

One-component paint can carry out later coating after drying; two-component paint is suggested to have the coating time intervals as follows:

| Substrate temperature | 5℃ | 20℃ | 30℃ |

| Shortest | 48h | 24h | 16h |

| Longest | No limit | ||