Composition: The product is the two-component self-dry coating composed of Epoxy resin, zinc powder, pigment, additives, solvents etc.

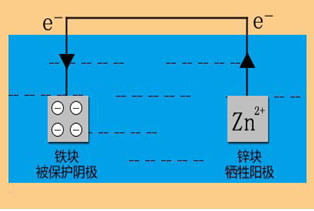

Performance: The epoxy zinc rich primer is produced by high quality zinc powder with high content of zinc powder, which can effectively protect the substrate and greatly enhance the anti-corrosion properties. The zinc powder of higher content has the cathodic protection to have electrochemical anti-corrosion function, and at the same time the generated zinc salt has good shielding and corrosion inhibition function. Welding with coatings may not affect the quality of welding, and the coating is not damaged by cutting or welding. As the heavy anti-corrosive primer, the epoxy zinc-rich primer can form matching system together with a variety of intermediate paint and finish paint, to have good coating compatibility.

|

|

|

High zinc content This primer use high-quality zinc powder, zinc content is high, can effectively protect the substrate, enhance the corrosion properties greatly |

Cathodic Protection Effect High content of zinc powder has electrochemical corrosion, and the generation of zinc salt has good shielding corrosion inhibition |

|

|

|

Weldability The coating does not affect the quality of welding, cutting or welding and will not be damage the coating. |

Strong adhesion The film has excellent adhesion to steel surface blasting. |

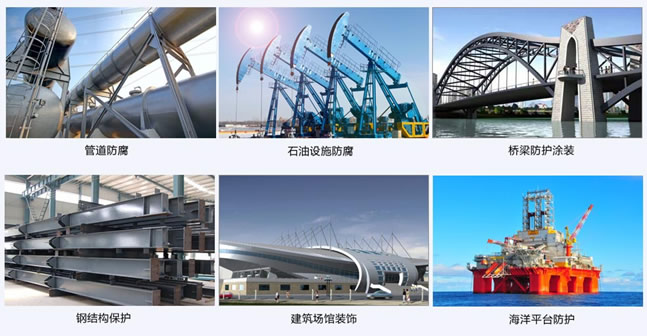

Application: The epoxy zinc-rich primer is one of the most widely used industrial anti-corrosion products, which is suitable for the steel rust protection under atmospheric environment and is widely applied in general corrosion prevention, chemical environment, ocean environment and other anticorrosion and weather resistant coatings.

Product specification

Mixing ratio: Group A: B=10:1

Technical parameters

| Item | Index | |

| Color and appearance of paint film | Gray, smooth surface without light | |

| Constructability | No obstacle to the film | |

| Drying time | surface dry | ≤1h |

| hard dry | ≤24h | |

| Applicable period(23±2℃) | 3h | |

| Impact strength | 50kg/cm | |

| Adhesion (level) | 1 | |

| Zinc content | ≥70% | |

| weather fastness(Natural exposure for 6 months) | No bubble, no rust, no cracking, no peeling | |

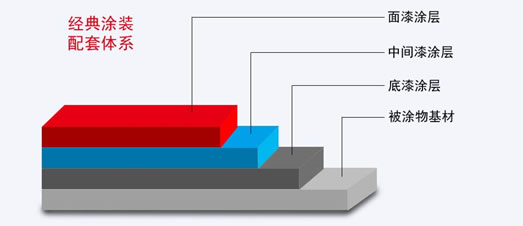

Supporting system

The epoxy zinc rich primer can be applied to various industrial environments:

•Anti-corrosion of steel structure: epoxy zinc-rich primer + epoxy micaceous iron oxide intermediate paint + Aliphatic series isocyanate paint

•Bridge preservation: epoxy zinc-rich primer + epoxy micaceous iron oxide intermediate paint + Fluorocarbon topcoat;

•Construction venue decoration: epoxy zinc-rich primer + epoxy micaceous iron oxide intermediate paint + Fluorocarbon metal paint

Construction method

1、Base material processing

The coated base material surface must carry out thorough removal of grease, scale, rust, old coating, and etc., using shot or sand blasting method, to reach Sweden derusting standard Sa2.5 grade and roughness of 30-70μm, manual derusting methods can also be adopted to reach Sweden derusting standard St3 grade and roughness of 30-70μm.

2、Mixture

According to the weight ratio (the label on the product packaging shall prevail)

When mixing, under the condition of stirring the main agent continuously, slowly pour in curing agent to make it fully ad evenly stirred.

20 min after curing of the well mixed coating, filter with 60-80mesh screen, and pour into another container for spare use.

The mixed coating is valid for 3 hours; please arrange the use according to the construction progress.

3、Construction conditions

Coating operation shall be performed as soon as possible after the substrate processing, generally not exceeding 8 hours. The substrate surface temperature and environmental temperature are generally no less than 10℃, the surface temperature shall be at least 3℃ higher than the dew point temperature, and the relative humidity of the air shall not exceed 85%.

4、Coating method

This coating can use brush coating, airless spraying and auxiliary air spraying method for construction.

5、Dilution

Generally the coating shall use the matching thinner to adjust viscosity and cleaning tools.

6、Coating intervals

One-component paint can carry out later coating after drying; two-component paint is suggested to have the coating time intervals as follows:

| Substrate temperature | 5℃ | 20℃ | 30℃ |

| Shortest | 48h | 24h | 16h |

| Longest | 12 months | ||